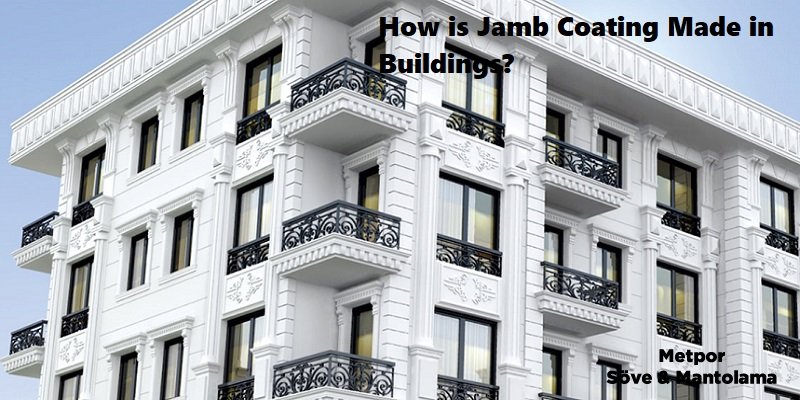

How is External Wall Jamb Coating Made in Buildings?

In our age, "jamb models" as exterior cladding of buildings is a building material produced from EPS styrofoam material, which attracts a lot of attention. Especially Istanbul jamb companies serve all of Turkey, especially Istanbul, with different jamb samples and different sheathing material types. We are in the first place as Metpor Jamb & Sheathing Company, which is one of the companies that brings us the most comprehensive and original jamb coating types in our country in terms of "jamb cladding visuals".

Exterior Jamb Cladding Models

Window jamb models are in desired dimensions and sizes, but they can be produced in different patterns and thicknesses. Styrofoam window jamb models, which are a fast and simple program, are both practical and other "jamb coating", without the need to spend very high budgets in order to obtain a qualified, superior view architecturally, and without the need for a long-term and tiring exterior coating process that is not exactly what you want. It is the most ideal insulation material in terms of price performance among the "materials" options. There are many types of styrofoam cladding as interior wall jambs and interior wall jambs.

Sheathing companies that make exterior applications in buildings do not manufacture jambs. Metpor Jamb and Sheathing Jamb is an Istanbul - based manufacturer, which is shown as an example in the production of jamb coating and sheathing material .

How is Exterior Jamb Cladding Made ?

- It is determined by taking the necessary measurements on the surfaces on which the jamb coating will be made in the buildings. Joints are calculated with the help of a miter.

- The jamb models suitable for the project are cut to the required dimensions and the junctions of the jamb ends are determined with miter angles and 45º angles.

- It is calculated according to the outer or inner miter direction and the miter is cut.

- Before the jamb coating application, the styrofoam adhesive prepared by using a mixer is plastered on the back surface of the jamb with a notched trowel and adhered to the place where it is adhered by vacuuming. The jamb is ideally adhered to the window modeling.

- The applied jamb coating is fixed at ideal points by means of nails, and in this way, the jamb coatings are mechanically attached to the floor until the adhesive dries.

Jamb Coating Models

It is filled with flexible acrylic plaster from the places fixed with nails, and the seam repair applied by brush or styrofoam takes a perfect basis. Adhesives and acrylic repair plaster overflowing between exterior cladding materials or joints are corrected with a brush and spatula. The indentations and roughnesses that will occur in the repaired areas are applied by checking.

After drying, the protrusions are eliminated by sandpaper. Thus, the jamb coating program is made ready for painting, and the seam modification is finalized in order to avoid capillary cracks. Exterior cladding with jambs is defined as an important element that will complete the thermal insulation application of buildings.

Plates exposed to precipitation on the façade of the building, jambs, windowsills, floor wipes, that is, all visual materials should be allowed to dry before the paint program is applied, otherwise the moisture that will remain under the paint will try to reach the upper surface of the paint over time, and cracks will appear in the paint.

After drying, it should be finished by priming and painting. Window jamb coatings should not be considered as materials capable of providing thermal insulation alone. It should be used together with the exterior sheathing application that will support the insulation on the building facade.

Jamb Coating Types

What is CNC EPS Polystyrene Jamb? Why is it advantageous?. EPS Polystyrene house jamb coating models offer us many advantages. It gives the designer as much flexibility as possible in his work. The designer offers the advantage of drawing in 1/1 scale by preparing the jamb coating design for the building himself. According to this; The project of the jamb (jambar drawings ) is transmitted to the CNC Operator who cuts the jamb cladding materials in autocad file format.

In general, DWG or DXF extensions are preferred. The operator prepares the manufacturing assembly of the jamb EPS styrofoam blocks. The CNC jamb cutting machine automatically covers the products, of which jamb models are cut, with jamb mortar, by obtaining a smooth surface thanks to the coating machine device.

Afterwards, the products of house jamb cladding models, which are left to dry, are left to dry for an average of 48 - 72 hours and then shipped to the construction site of the building where the exterior wall application will be made for exterior cladding. How is floor wipe applied? If we ask, we can say that it is done using the same method as the jamb application.

Metpor

info@metpordekor.com

Okunma Sayısı : 187