Sheathing, Exterior "Heat Insulation" Types

Types of Exterior Sheathing

Contents;

- Types of Exterior Sheathing

- Interior Sheathing Types

- XPS Sheathing Types

- Sheathing Foam

- Mansion Printing Sheathing Types

- Fluted Coating Types

- Jamb Coating Types

- Terracotta Coating Types

- Middle Sheathing Types

- Sheathing on Floors

- Sheathing Type on Roofs

- Eps Sheathing (Classic Anchored Flat Sheathing) Type

- Carbon EPS Insulation Types

- Stone Wool Sheathing Types

What is sheathing in buildings ? We have explained this question in detail in our previous articles. Our current topic is sheathing types .

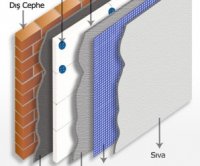

Heat insulation board ; The variation of covering the exterior of the building with thermal insulation materials in order to ensure the safety of the cold air wave coming from the outside and the heat inside the building is" exterior cladding " application.

There are many types of sheathing. The exterior cladding program is the most ongoing thermal insulation system in the 21st century. Generally , there are thousands of construction sites within the province of Istanbul . There are many sheathing companies on the Anatolian Side and the European Side of Istanbul. Thermal insulation materials and types used : EPS, XPS, Carbon reinforced EPS, Rockwool thermal insulation boards.

Types of Interior Sheathing

It is applied like exterior sheathing types. However, the process is reversed here, and the interior sheathing program is made and painted in order to cover the interior walls with thermal insulation materials, and it provides the opportunity to make drywall types on the coating. Materials used: EPS, XPS, Carbon EPS, thermal insulation plates can be used.

Middle Sheathing Foam Types

The double skin outer wall system created by the two massive building shells and the thermal insulation layer between them is called the middle heat insulated outer wall. Various materials used : Glass wool, rock wool, wood wool, sheep wool, mineral fiber plate thermal insulation materials, EPS and XPS rigid foam, polyurethane rigid foam, expanded ureaformaldehyde foam, etc., in the outer walls with thermal insulation in the middle. used as thermal insulation materials with the aim of using " exterior sheathing materials " that make plaque , glass foam or expanded perlite or granular insulating filling materials such as verniculite, pumice etc.are applications of exterior sheathing types .

Types of Sheathing in Floors

XPS thermal insulation plate types , which are waterproof and have high compression strength, should be used for floors that fit on the ground. Sheathing on floors located above unheated basements is one of the techniques of sheathing types that ensure the prevention of heat losses arising from the floors of the ground floors by determining the basement ceiling. For exterior sheathing prices , you can find information from the link.

Sheathing on Roofs - Types of Insulation

When it is necessary to walk between the roof, a walkway should be built with planks on wooden frames. If the insulation material types will be exposed to load, hard sheathing material types in the form of plates should be used instead of mattress-style insulation types.

A smooth floor is provided by cleaning the top of the roof slab on which exterior sheathing will be made from dust, dirt and mortar residues, or by making a trowel polished thin screed program on the slab concrete. According to the results of the condensation investigation on a smooth surface, a vapor stabilizer is laid and the sheathing materials, the thicknessof which are determined according to the TS 825 Standard for Thermal Insulation Rules in Buildings , are applied in the colors of the jacketing models.

Types of Sheathing According to Materials

EPS Exterior Sheathing ; Expanded polystyrene foam (EPS) is a type of thermal insulation material obtained from petroleum, thermoplastic, closed-pored, white colored variant . There is dry air, 98% of which is immovable, inside the many small closed porous cells (3-6 billion in 1 m3 EPS) within the EPS sheathing boards.

In this way, the economical and superior thermal insulation properties of EPS thermal insulation boards are provided . The performance of the product remains constant throughout its lifetime. Its thickness does not become thinner, its thermal conductivity does not decrease, and its properties do not deteriorate. EPS is produced in desired densities. EPS sheathing sheets , which are generally used in 15 - 30 kg/m3 densities for exterior sheathing purposes, are very light, and sheathing types , exterior cladding types and prices that do not bring much load to the facade are among the programs. Applications: Building interior and exterior walls.

Carbon Exterior Sheathing Types (Carbon Reinforced Eps Thermal Insulation Board Variant)

Carbon reinforced EPS styrofoam is one of the best jacketing materials. It is an EPS (Expanded Polystyrene) type whose insulation feature is designed with the help of graphite heat reflectors in its contentIt is these graphite heat reflectors that give the carbon EPS its gray color. Graphite reflects hot and cold better, providing better thermal insulation than conventional EPS . In the B1 fire class category , EPS styrofoam with carbon is included in the Thermal Conductivity Group 035 even at low densities(TS 7316 EN 13163).

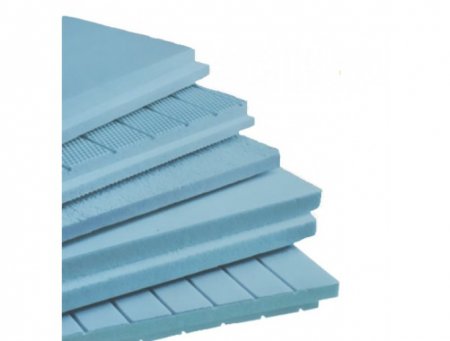

It is one of the " exterior jacketing types " techniques that provide the same thermal insulation with much less or thinner material compared to conventional EPS insulation materials, with the help of the thermal conductivity group of 035 at low densities . Applications: Building interior and exterior walls. XPS INSULATION Extrude polystyrene rigid foam XPS, made of polystyrene, is an " exterior sheathing " material with homogeneous cell structure, manufactured to provide insulation.

Best Sheathing Materials

Extruded Polystyrene materials (XPS) are materials that have high compressive strength, good thermal conductivity, are in B1 fire category, do not absorb water and are not affected by moisture. Applications: Building interior and exterior walls. It is among the types of sheathing used in floor insulations, basement levels, and roof insulation .

ROCK WOOL INSULATION ; Stone wool is formed as a result of melting basalt stone at 1350°C - 1400°C and turning it into fiber. Basalt stone has the feature of inorganic raw material and is supplied locally. Stone wool can be produced in different sizes and technical specifications depending on the place of use and target.

Rock wool , which can be produced in the form of mattress, sheet (plate), pipe and bulk with different coating materials , is among the " quality sheathing types " used for thermal insulation , sound insulation, acoustic planning and fire insulation . You can also benefit from our article on exterior cladding panels .

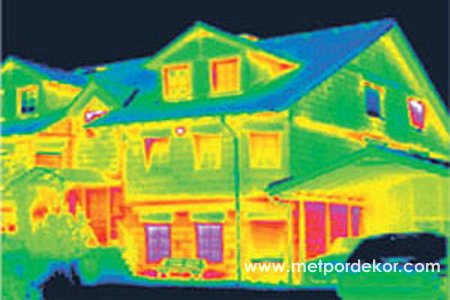

Heating of the outer walls of residential buildings is always preferred for thermal insulation of interiors. This is due to the fact that external insulation is more efficient; With internal insulation there is always 8-15% heat loss.

In addition, the humidity level of the room is increased by moving the "dew point" into the moisture-filled insulation together with the inner insulation, causing mold growth on the walls, destruction of the wall surface and its finishing. In other words, the room is still cold (because a salt insulation cannot prevent heat loss), but salt is.

Finally, installing insulation indoors takes up space, reducing usable floor space.

Also, there are situations when internal insulation is the only possible way to normalize the temperature. Installation technology allows strict adherence to avoid the unpleasant effects of thermal insulation. Be sure to take care of high-quality ventilation as well as vapor and waterproof surfaces. A standard supply system is often insufficient, it is necessary to install a forced air circulation system or use windows with special valves that provide air exchange.

There are 2 known types of Expanded Polystyrene

- foam (otherwise - foam) and extruded. It is a series of air-filled joint bubbles. The extruded material is different because each air gap is different from the other.

Styrofoam is suitable for external and internal warming, characterized by high thermal insulation indicators. Requires reliable vapor barrier as it is not vapor permeable. This is noticeable given the low moisture resistance of the foam, which obliges the installation of hydraulic protection.

In general, the material is inexpensive, lightweight, and easy to cut and install (glue). Material plates of various sizes and thicknesses are produced for the needs of the buyer. Secondly, it directly affects the thermal conductivity.

The insulation material used in construction to control the heat output of the conventional material from the indoor environment is called the insulation material used to prevent the outdoor heat in the indoor material .

Another Type of Sheathing ;

Types of Insulation with Jointed Sheathing and Insulation Printing Coatings

Fugalı Sheathing is the best jacketing material products used with the aim of preventing expansion and cracking among exterior coating materials and providing an aesthetic view. In the jointed sheathing application program, the jointed exterior wall models were among the most preferred exterior cladding types for 2018.

It is used both because it offers an aesthetic visuality and because it provides a finish without creating an addition during the application of decorative plaster and paint. Jointed coatings and siding printing coatings are also produced as ready-to-paint, self-plastered sheathing types and exterior wall coating sheets . In the product range of METPOR " exterior sheathing " products, there are many ready-made panels, namely decorative exterior coating types, namely " sheathing types ".

Exterior Cladding Types and Prices

You can find details in the articles on exterior cladding types and prices, building exteriorsheathingmodels, sheathing foam types . When the exterior cladding of the buildings made, the energy savings that will emerge and this savings contribute to the family and country economy. Interior ceilings, cavity walls and exterior walls come first as the areas that need to be sheathed .eps styrofoamSince the material can be easily cut in the desired forms in cnc machines and can be produced by direct printing method, it can be produced by mold method.exterior cladding models It offers advantages in making flexible designs for These material types, which offer different variant options, and this unique feature, make these materials one step ahead.

In order to make sheathing without installing scaffolding, interior sheathing types should be applied. It is not necessary to get permission from the municipality for the sheathing application . Therefore, there is no such document as "sheathing municipality permit".

Exterior cladding and sheathing types , logically, is the thermal insulation of the building with the siding technique. These insulation applications are defined as the most useful thermal insulation technique since they prevent the building components from being affected by heat changes.

In all modern building technologies, thermal insulation is the main building component. However, it was not used in almost any of the buildings since it was not compulsory in our country in the past.

Metpor

info@metpordekor.com

Okunma Sayısı : 184