Payanda Nedir: 2026'da da Evinizin Estetiği ve

Payanda Nedir? 2026'da Yapıların Gizli Tasarım Gücü ve Tarihi Mirasın Koruyucusu ..

Devamını OkuYalı Baskı Dış Cephe Kaplama: 2026'nın En

Yalı Baskı Dış Cephe Kaplama: Estetik, Dayanıklılık ve Isı Yalıtımı Bir Arada ..

Devamını OkuMantolama Nasıl Yapılır? Adım Adım Uygulama

-

Metpor

Mantolama Nasıl Yapılır? 2026 Uygulama Rehberi ve Detayları Enerji verimliliği ve konfor ..

Devamını OkuDış Cephe Kaplama Fiyatları: Türkiye'nin En İyi

-

Mete Yılmaz

Güncel Dış Cephe Kaplama Fiyatları: 2026'da Binanıza Akılcı Bir Yatırım Yapın! ..

Devamını OkuMantolama: 2026 Yılında Dış Cephe Isı Yalıtımı

-

Mete Yılmaz

Mantolama Nedir? Binalarınız İçin Enerji Verimliliği ve Konforun Anahtarı Kışın sıcak, ..

Devamını OkuMantolama Malzemeleri: Binanıza En Uygun Yalıtım

-

Metpor

Mantolama Malzemeleri: Doğru Yalıtımın Temel Taşları Binanızın enerji verimliliğini, ..

Devamını OkuFugalı Dış Cephe Kaplama Fiyatları ve 2026

-

Metpor

2026 Güncel Fugalı Dış Cephe Kaplama Fiyatları: Binanıza Akılcı Bir Yatırım Yapın! ..

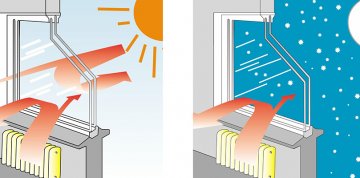

Devamını OkuIsı Yalıtımı Nedir? 2026 Yılında Evinizde Konfor

-

Mete Yılmaz

Isı Yalıtımı Nedir? Evinizde Konfor ve Enerji Tasarrufunun Anahtarı Yaşam alanlarımızda ..

Devamını OkuSöve Nedir? Modern Mimarinin Minimalist

-

Metpor

Söve Nedir? 2026 Yılında Binalarınıza Estetik ve Fonksiyonel Değer Katan Mimari ..

Devamını OkuSöve Fiyatları 2026: Estetik ve Kaliteye

-

Mete Yılmaz

2026 Güncel Söve Fiyatları: Binanıza Estetik ve Değer Katın! İstanbul'un mimari dokusuna ..

Devamını OkuMantolama Çeşitleri 2026: Evinize En Uygun

-

Metpor

Mantolama Çeşitleri: Binanız İçin En Doğru Isı Yalıtımını Keşfedin Binanızın enerji ..

Devamını OkuTadilat Nedir? Hayallerinizdeki Evi

-

Metpor

Tadilat Nedir? Hayallerinizdeki Evi Gerçekleştirmenin Anahtarı! Tadilat bir bakıma ..

Devamını Oku2005 - 2025 MT Web Team | Metpor Söve & Mantolama Ürünleri - Metpordekor.com

Okunma Sayısı : 76 643

Mete Yılmaz