2025 Yılı Dış Cephe Kaplama Modelleri:

Estetiği Yeniden Tanımlayın: Dış Cephe Kaplama Modelleri Binanızın dış görünümünü ..

Devamını OkuSöve Modelleri: Mimari Estetiğin Yeni Yüzü

Söve Modelleri: Yapılarınıza Zarafet Katan Tasarımlar Binalarınızın dış cephesine ..

Devamını OkuSöve Nedir? Modern Mimarinin Minimalist

-

Metpor

Söve Nedir? Binalarınıza Estetik ve Fonksiyonel Değer Katan Mimari Dokunuşlar Binaların ..

Devamını OkuSade ve Şık: Düz Söve Modelleri ile Evlerinize

-

Metpor

Düz Söve Modelleri: Minimalizmin Estetiği Düz söve modelleri , minimalizmin sade ve şık ..

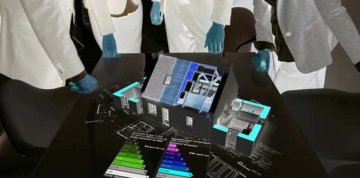

Devamını OkuMantolama Rehberi: 2025 EPS Strafor Fiyatları,

-

Mete Yılmaz

Mantolama 2025: Kapsamlı Enerji Tasarrufu ve Isı Yalıtımı Rehberi 2025 mantolama ..

Devamını OkuMetpor'dan Dış Cephe Kaplama Rehberi: 2025 EPS

-

Mete Yılmaz

Dış Cephe Kaplama Tendleri 2025: Estetik, Üstün Yalıtım ve Maksimum Dayanıklılık Rehberi ..

Devamını OkuMantolama Çeşitleri: Evinize En Uygun Yalıtım

-

Metpor

Mantolama Çeşitleri: Binanız İçin En Doğru Isı Yalıtımını Keşfedin Binanızın enerji ..

Devamını OkuDış Cephe Kaplama Fiyatları: Türkiye'nin En İyi

-

Mete Yılmaz

Güncel Dış Cephe Kaplama Fiyatları: Binanıza Akılcı Bir Yatırım Yapın! İstanbul'un ..

Devamını OkuFuga Nedir? Dış Cephelerde Estetik ve Fonksiyonel

-

Metpor

Fuga Nedir? Cephede Estetik ve Fonksiyonel Çözüm Rehberi Binaların dış cephesinde sıkça ..

Devamını OkuMantolama: Dış Cephe Isı Yalıtımı ile Enerji

-

Mete Yılmaz

Mantolama Nedir? Binalarınız İçin Enerji Verimliliği ve Konforun Anahtarı Kışın sıcak, ..

Devamını OkuCephe Sistemleri Çeşitleri

-

Metpor

Mantolama: İstanbul'da Enerji Tasarrufunun ve Konforun Mimarı Kışın sıcacık, yazın ferah ..

Devamını OkuMantolama Yaptıranların Yorumları

-

Metpor

Mantolama Yaptıranların Yorumları: Gerçek Deneyimler, Gerçek Memnuniyet Mantolama ..

Devamını Oku2005 - 2025 MT Web Team | Metpor Söve & Mantolama Ürünleri - Metpordekor.com

Okunma Sayısı : 181 628

Mete Yılmaz